Iron ore exports, which had begun in 1907 with 200,000 tons, reached their peak in 1913 with 987,562 tons, representing 10% of the national production of iron ore.

The success of the Compañía Minera de Sierra Menera was interrupted during the World War I. The price increase of raw materials such as coal, essential in the processes of generating nodules and briquettes, as well as a change in demand towards processed steel products, caused a significant reduction in ore exports as well as a growing debt. All this prevented the company from investing in the project to set up a steelworks in Sagunto.

The same is not the case with the shipping company Sota and Aznar, the first in Spain at the time in terms of fleet size. During World War I it benefited enormously from the increase in freight rates and exports to the belligerent countries. Between 1914 and 1919, this shipping company obtained profits of 114 million Spanish pesetas.

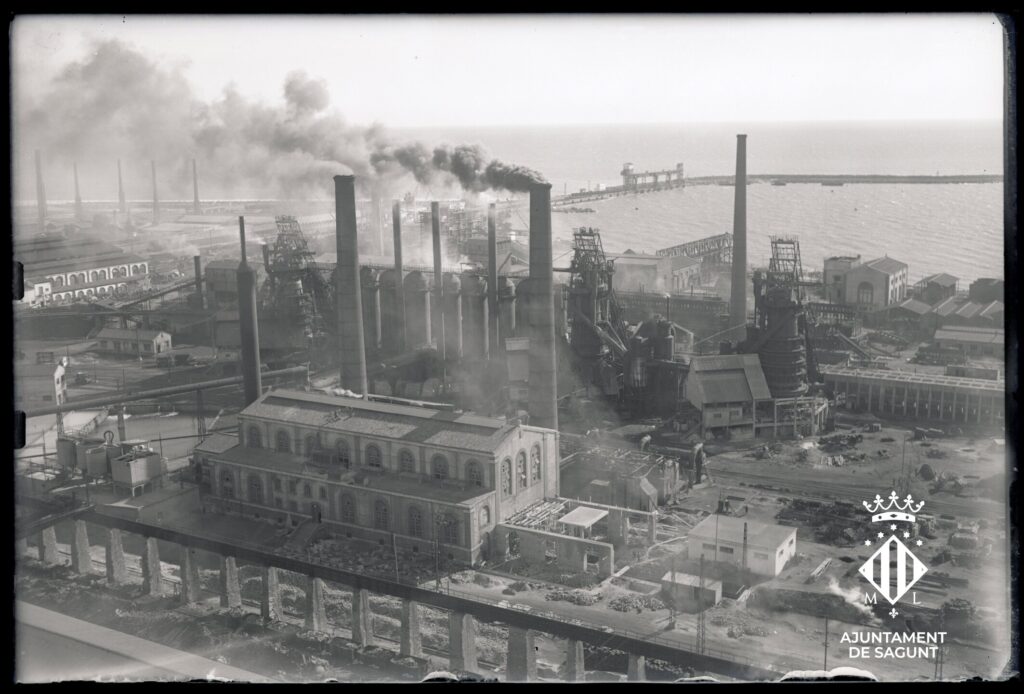

The difficulties to export iron ore, the boom of the steel industry in Europe and the great availability of capital of Sota and Aznar, were the final push towards the installation of the blast furnaces next to the wharf in the port of Sagunto.

The Compañía Siderúrgica del Mediterráneo was founded in Bilbao in August 1917, with a capital stock of one hundred million pesetas, and on January 6, 1923, the first casting of blast furnace was obtained.

Three steel mill furnaces and the rolling mills were started up on 31 August 1924. On 14 June 1926 the second blast furnace and the heavy plate mill were put into operation.

The blast furnaces were only in production for a short time as the severe 1929 world crisis affected the steel industry, causing the shutdown of the second blast furnace in 1930. The first blast furnace was also stopped only two years later. The production was discontinued until 1941.

During the Civil War, along with the railways, the port was badly damaged by aerial bombardment. However, the interest in taking control of the factory prevented the bombing from destroying the steelworks facilities.

During the war the steel mill remained in operation, as did the rolling mills and factories, manufacturing mostly artillery shells for the “Factory number 15 of the Under-Secretariat of Armament of the Republic”.

Between 1939 and 1941, the facilities of the Compañía Siderúrgica del Mediterráneo, which had been confiscated by the Franco regime from the Sota family and handed over to the Aznar family, were repaired with funds from the German government to extract the ore and send it to Nazi Germany.

Altos Hornos de Vizcaya acquired the Compañía Siderúrgica del Mediterráneo in December 1940. It consequently led to a dispute between the two metallurgy companies for the ownership of the port This dispute lasted until 1961, when they signed, in Bilbao, the definitive agreement between both companies for the use and leisure use of the port space and facilities.

In 1954, the third and last blast furnace was built and production reached the amount of 200,000 tons.

In 1965, the North American company United States Steel became a shareholder of Altos Hornos de Vizcaya , launching an ambitious expansion plan called the Sagunto Plan, with the aim of doubling production, which was achieved in 1970, reaching 536,000 tons of steel.

In 1971 the company Altos Hornos del Mediterráneo was created, majority of which owned by Altos Hornos de Vizcaya and its technological partner United States Steel, to which the Franco government awarded the execution of the IV Integral Iron and Steel Plant. This plant was planned based on the strong growth in demand experienced in the 1960s, to obtain a production of 6 million tons per year, higher than what was being obtained in Spain by the three existing integrated steel mills. Nevertheless, the economic crisis of 1973 led to a long-lasting steel crisis in 1975, which resulted in substantial losses for the company and the industry as a whole

The fierce disputes over the location of a new hot strip mill between the Asturias, Vizcaya and Valencia steel mills led to the commissioning of a study by a foreign consultant, Kawasaki Steel Corporation, which concluded that the right place to install the new hot strip mill was “next to the cold strip mill at the Sagunto plant, which is one of the most advanced in the world” and rejected the proposal to extend the existing mills at Aviles and Ansio.

Internal regional pressures and Spain’s accession negotiations with the European Communities limited investments in Altos Hornos del Mediterráneo. Thus, the Royal Decree on investments in the integrated steel industry of 6 July 1983 only authorised investments in the finishing installations, allowing the cold rolling mill, which had entered into service in 1976 as the first phase of what was to become the Fourth Integrated Steel Plant, to be kept, but did not authorise investments in the hot strip mill. This resolution led to the definitive closure of the headworks facilities, which had already halted their activity on 4 February 1983, when the president of Altos Hornos del Mediterráneo ordered the closure of secong blast furnace.

The activity of Altos Hornos del Mediterráneo ceased completely on 5 October 1984, putting an end to the project that had intended to turn Sagunto into “the most competitive steelworks in the world and which would produce the cheapest steel in the world” (George S. Moore, 1974).